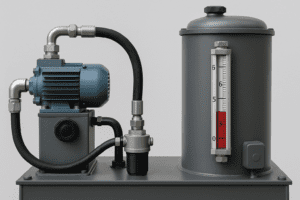

Understanding Industrial Procurement’s Role in Operational Finance

Traditionally seen as a cost center, procurement—especially in the context of industrial process instrumentation—can actually serve as a powerful profit driver. By strategically sourcing high-quality instruments, businesses can enhance process accuracy, product quality, customer satisfaction, and overall operational efficiency. Thoughtful procurement choices also strengthen documentation, traceability, vendor partnerships, and supply chain resilience, while mitigating risk and reinforcing competitive advantages. With a focus on premium instrumentation and strong supplier collaboration, companies can turn procurement into a key contributor to revenue growth and market differentiation.