Water & Wastewater

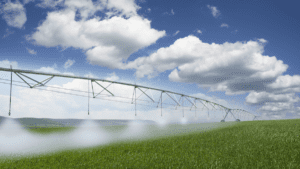

There is likely no engineering domain more quintessential to human existence than managing water. Across civilized history, humans have diverted water out of the ecosystem, used it for some functional purpose, and returned what was left over, all while figuring out ways to make that water safe, clean, and dependable. Known today as the Water and Wastewater Industry, the goals remain the same – only now, water is managed at global scales, serving the needs of billions.

CHALLENGES

Regional, municipal, and commercial water systems alike all share common challenges spanning quality, reliability, cost, and safety concerns. Individual facilities struggle with solving waste and efficiency problems, while regional distribution networks focus on declining availability and aquifer quality. The work ahead in managing the water frontier will be tough, but not impossible.

A FUTURE OF LOOMING SCARCITY

➤ By some measures, 2.1 billion people worldwide lack access to safe, reliable water, of which nearly 50 million are found in the US. Industrial manufacturers experience the impacts of such statistics in rising water supply and wastewater discharge costs, as well as increasing regulatory and public interests demanding to reduce consumption. Farther ahead, heightened levels of in-plant pre-treatment, post-treatment, and reuse are all but inevitable.

HEIGHTENED QUALITY CONCERNS

➤ Major municipal water infrastructure draws from reservoirs, groundwater aquifers, and rivers, and will discharge treated wastewater back into these same bodies. As aquifers dry up or are overused, contaminants become concentrated, and organic cycles that break down trace byproducts slow down. For these reasons, water quality degrades, driving increased treatment equipment and costs first of municipalities, then ultimately of individual users.

OUT OF SIGHT, OUT OF MIND

➤ Being one of our most omnipresent pillars of infrastructure both at the societal and in-plant levels, water distribution systems are often old, under-maintained, and expected to ‘just work’. Systems tend to slow down, succumb to leaks and waste, fall in energy efficiency, and expose users to unexpected outages due to failure. Modernizing water infrastructure can be costly if left unappreciated for too long, leading to perpetually kicking the maintenance and upgrade can far down the road.

SOLUTIONS

While we’re not suggesting that our customers tackle global water problems (unless you can!), Whitman Controls does stand ready to support your water efficiency aspirations with advanced instrumentation and process controls know-how. Whether launching a plantwide water optimization project or simply maintaining an existing wastewater system, we offer multiple solutions specifically geared towards sustaining water resources for generations to come.

Economy Class Product Suite

Whitman Controls offers a selection of economical, low-cost, in-stock sensor models strategically targeting your routine control applications. We have specific temperature, pressure, vacuum, and level sensors designed to be 'set and forget' workhorses where simplicity outweighs the need for bells and whistles.

Simplified Standardization

Our product catalog includes a wide range of solutions that span in-process as well as central utility applications, and everything in between. Standardizing on a common instrument manufacturer across multiple areas of a plant vastly simplifies procurement, maintenance, troubleshooting, and support, not to mention new project developments – benefits that are especially pertinent to large, complex manufacturing sites.

Extensive Application Engineering Support

Whenever you face a new application, unique challenge, difficult design constraint, or other technical concern, Whitman's application engineers stand ready to support you with their broad experience and honed expertise across nearly all industries. Our ability to troubleshoot and resolve application challenges is a testament to our dedication to our customers’ success long after their purchase is complete.

Conventional Solutions to Emergent Applications

While an application may be novel in its field, diligent engineering review often finds that a standard or semi-standard solution can be made up by piecing together conventional components – the magic being in the way these components are applied and configured. Our experienced engineers can help break down complex, emergent projects to help you navigate options between standard and custom instruments.

WATER & WASTEWATER APPLICATION

PRODUCTS

Whitman Controls offers multiple instrument, switch, and transmitter models that are engineered to match the demands of the Water and the Wastewater Industry, such as these below related products

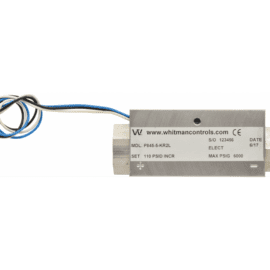

W117G Ultra Pure Pressure Switch

The W117G Ultra Pure Stainless Steel Pressure Switches have all welded stainless steel interiors which are Helium leak checked to pass 4 x 10-9 Std CC/Sec. These switches are used in silicon wafer ovens, numerous medical devices and other applications where even the slightest impurities are not tolerated.

L60 Stainless Steel Vertical Level Switch

The Whitman Controls L60 Series Heavy Duty Vertical Mount 2” Sphere Stainless Steel Liquid Level switch consists of a stainless steel stem and float which afford the end user maximum versatility in functionality and operating environment. These levels can withstand system pressure to 975 PSIG (67 BAR) and an extensive temperature operating range. They are commonly used in potable water, hot water, and in various acids and solvents.

T150D Adjustable Stainless Steel Temperature Switch

The T150D Adjustable Stainless Steel Miniature Temperature Switches provide the end-user with a wide range of functionality without impacting durability. The T150 is designed for use up to 510°F but can withstand temperatures up to 800°F while still protecting the set point and life of the switch. The limit filled, saturated vapor sensor is in direct contact with the temperature-sensing outer shell producing fast response and accurate temperature control. The external setting scale provides full range adjustment and the external lock screw allows for easy adjustment of set point.

W117 In-Stock Switch

The W117 In-Stock switches come with fewer options than our customizable W117 switches, but are available for same day shipping when an order is placed prior to 1pm EST. These Ultra Pure Stainless Steel Pressure Switches have all welded stainless steel interiors which are Helium leak checked to pass 4 x 10-9 Std CC/Sec. The W117 is used in silicon wafer ovens, numerous medical devices and other applications where even the slightest impurities are not tolerated.

P845 Differential Pressure Switches

The Whitman Controls P845 Differential Pressure Switches are rugged and versatile, with excellent by-pass characteristics and the ability to handle a wide variety of media to 6,000 PSIG and set point ranges to 250 PSID. These switches are NEMA 4 rated and can tolerate submersion. They are commonly used across oil and water filter heads to detect when a filter element needs changing. It may be mounted in any orientation and is capable of carrying light to moderate mechanical shock and vibratory loads.

KEY APPLICATIONS

Using E-Procurement for Instrumentation Contracts

Functional Safety Controls – Protecting Your Employees and Processes

Forging Rewarding Relationships in Industrial Instrumentation Supply

Sustainable Water Management Using Advanced Automation