Pulp & Paper

Aside from the motor vehicle market, few other sectors are experiencing as large of a rebirth as the Pulp & Paper Industry today. Books and printed graphical products are hastily being replaced by digital content, while in their place we find emergent packaging, personal hygiene, and fiber products rapidly expanding. As the industry adapts to the demands ahead, new pulp and paper technologies are constantly proven to be the ideal, sustainable, natural solution of choice.

CHALLENGES

Forest products present a particularly tough set of manufacturing challenges, starting with the variability of a naturally grown raw material (trees), and extending to the fragility of final paper goods. Assuring process integrity and quality across this entire supply chain is imperative, a fact that Whitman Controls fully embodies with every one of our process instrumentation solutions.

NATURAL THREATS

➤ As global climates continue to fluctuate, forest products are under increasing natural threat. Insect infestations, wildfire, drought, extreme wind and rain – different regions experience different abnormalities, but all seem to be trending more severe as years go on. As these impacts stack up, pulp mills are seeing wider variation and degrading quality in their feedstocks, making downstream paper processes all the more difficult to control.

RESOURCE INTENSITY

➤ Paper manufacturing is one of the most water-intensive processes around, using as much as 45 gallons of water to produce 1 pound of paper (in plants with zero water recycling). With water recycling, this number can get down to 1 gallon of water per pound of paper, along with water reuse up to 10 times before discharge. Counting land and electricity, paper production is very resource heavy, but also equally ripe for efficiency improvements.

LONG-TERM SUSTAINABILITY

➤ Building upon the above two points, the long-term sustainability of forest products is an evolving topic, as climate, resource, and end product factors change over time. New manufacturing processes, energy strategies, environmental protections, and resource economies will be needed to keep the industry competitive, as well as socially responsible. In addition, expanding regulatory requirements are also expected, targeting overall emissions, yields, waste, and efficiency across the Pulp & Paper supply chain.

SOLUTIONS

World-class Pulp & Paper manufacturing combines advanced automation solutions with highly efficient mechanical systems, together cutting resource consumption, improving yields, and streamlining adaptation to new product lineups. For process, water, chemical, steam, compressed gas, and wastewater services, Whitman Controls offers robust sensor solutions utilized in mills of all scales.

Extensive Application Engineering Support

Whenever you face a new application, unique challenge, difficult design constraint, or other technical concern, Whitman's application engineers stand ready to support you with their broad experience and honed expertise across nearly all industries. Our ability to troubleshoot and resolve application challenges is a testament to our dedication to our customers’ success long after their purchase is complete.

ISO Quality Control

Our product quality may speak for itself, but how can we assure this before you put our instruments into use? Whitman Controls is an ISO 9001 Certified business, providing you with the assurance that our products are entirely designed, manufactured, tested, and delivered using third-party verified practices, complete with total process documentation, material traceability, and chain of custody control.

Standardized Central Plant Packages

Central utility and common plant services share many overlapping requirements, which benefit immensely from a standardized, uniform instrumentation package solution. Whitman helps lower costs and reduce complexity by working with our clients to standardize instrument kits, specifying similar fittings, wiring, ranges, housing styles, and other features into fewer part numbers. This also provides more interchangeability, less maintenance and operator training, and fewer spares to stock.

Full Product Customization and Value-Add

Our predefined product catalog of hundreds of instruments is only the tip of the iceberg here at Whitman Controls. We can fully customize virtually any of our product models to your exact needs. We're especially excited about emergent applications and highly technical challenges, and can help you with one-off R&D samples as well as high volume production runs of your World's First instrument design, plus custom wiring harnesses, adaptors, and kits.

PULP & PAPER APPLICATION

PRODUCTS

Whitman Controls offers multiple instrument, switch, and transmitter models that are engineered to match the demands of the Pulp & Paper Industry, such as these below related products.

P605 High Pressure Fine Adjustment Model

The P605 Pressure Switches are a line of severe application controls that can withstand massive pressure spikes from hydraulic systems. These switches can see pressure spikes to 9,000 psig without comprising switch integrity or functionality. They also afford the end user higher set points to complement more severe environments and low set point repeatability.

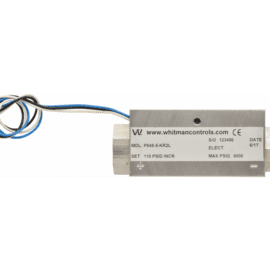

P845 Differential Pressure Switches

The Whitman Controls P845 Differential Pressure Switches are rugged and versatile, with excellent by-pass characteristics and the ability to handle a wide variety of media to 6,000 PSIG and set point ranges to 250 PSID. These switches are NEMA 4 rated and can tolerate submersion. They are commonly used across oil and water filter heads to detect when a filter element needs changing. It may be mounted in any orientation and is capable of carrying light to moderate mechanical shock and vibratory loads.

P802 Series High Pressure Stainless Steel Pressure Transducer

The P802 Series Pressure Transducers are all-welded stainless steel sensors with pressure ranges up to 20,000psig. These devices are highly configurable with numerous fitting and electrical connection options, allowing use across a range of media and applications. The composition of these units make them ideal in more rugged environments where accuracy of measurement is critical.

KEY APPLICATIONS - COMING SOON