HVAC

While the necessities of life might not officially include heating and air conditioning, most of us would be significantly impacted if we had to go through life completely exposed to our local climate without relief. The HVAC Industry provides us with this relief by heating, ventilating, and air conditioning indoor spaces to our comfort, thanks to advanced mechanical systems and sophisticated controls that keep outside weather outside, and cozy atmospheres within.

CHALLENGES

Back during the Industrial Revolution, the HVAC Industry was born of simple ventilating fans that converted mechanical power into air flow, where the core challenge was how to efficiently convert this energy for the most benefit. Today, we largely face the same core challenge, though now it’s expanded to massive scales and much more complex applications.

DESIGNING FOR THE UNKNOWN

➤ HVAC design criteria is mostly standardized by historic climate profiles and third-party performance requirements, but as annual weather cycles continue to break records year after year, system designers are faced with the need to solve for future conditions that are generally unpredictable. This trend leads to overdesign and unnecessary costs, a situation that can’t be averted until climates stabilize or designs reach near-perfect efficiencies.

ENERGY CONSERVATION AND PERPETUAL SCRUTINY

➤ The HVAC Industry is under constant barrage due to its direct relationship between energy consumed to produce comfortable human space, and the impacts of this energy’s consumption on the wider global environment. Some reports claim that HVAC systems consume 38% of building-related energy and up to 25% of all final energy worldwide, and growing. In turn, regulators increasingly aim parallel carrot-and-stick tactics at the HVAC Industry, including new regulations, audits, incentives, and certifications.

MISSION-CRITICAL ENVIRONMENT CONDITIONING

➤ Though some might disagree, conditioning a Miami home in 110°F weather is not mission-critical in the same way that maintaining positive, hygienic, sterile air flow into a hospital operating room during an emergency surgery would be. HVAC applications cover a wide range of zero-fault tolerance conditions across commercial, industrial, and institutional facilities, plus more exotic uses such as onboard seafaring vessels and in mine shafts extending miles into the earth.

SOLUTIONS

The path forward in the HVAC Industry is clear: new technological advancements coupled with world-class process controls will grant HVAC systems the energy efficiency, reliability, and scalability that regulators and end-users demand. Whitman Controls is ahead of the curve, offering a full lineup of temperature, pressure, vacuum, and flow sensors ideally suited for HVAC and refrigeration applications.

Efficiency as a Core Value

We value efficiency and energy conservation so much that we practice an organizational commitment to responsible manufacturing across the board. Our sensors are designed with simplicity in mind, using fewer materials with less waste from cradle to grave. Our electronics are tuned for long lives, high responsiveness, and high repeatability, combating energy-sucking drift and deadband. And much more!

ISO Quality Control

Our product quality may speak for itself, but how can we assure this before you put our instruments into use? Whitman Controls is an ISO 9001 Certified business, providing you with the assurance that our products are entirely designed, manufactured, tested, and delivered using third-party verified practices, complete with total process documentation, material traceability, and chain of custody control.

Extensive Application Engineering Support

Whenever you face a new application, unique challenge, difficult design constraint, or other technical concern, Whitman's application engineers stand ready to support you with their broad experience and honed expertise across nearly all industries. Our ability to troubleshoot and resolve application challenges is a testament to our dedication to our customers’ success long after their purchase is complete.

Full Product Customization and Value-Add

Our predefined product catalog of hundreds of instruments is only the tip of the iceberg here at Whitman Controls. We can fully customize virtually any of our product models to your exact needs. We're especially excited about emergent applications and highly technical challenges, and can help you with one-off R&D samples as well as high volume production runs of your World's First instrument design, plus custom wiring harnesses, adaptors, and kits.

HVAC APPLICATION

PRODUCTS

Whitman Controls offers multiple instrument, switch, and transmitter models that are engineered to match the demands of the HVAC Industry, such as these below related products.

W117G Ultra Pure Pressure Switch

The W117G Ultra Pure Stainless Steel Pressure Switches have all welded stainless steel interiors which are Helium leak checked to pass 4 x 10-9 Std CC/Sec. These switches are used in silicon wafer ovens, numerous medical devices and other applications where even the slightest impurities are not tolerated.

W117V Ultra Pure Vacuum Switch

The W117V Ultra Pure Stainless Steel Vacuum Switches have all welded stainless steel interiors which are Helium leak checked to pass 4 x 10-9 Std CC/Sec. These switches are used in silicon wafer ovens, numerous medical devices, and other applications where even the slightest impurities are not tolerated.

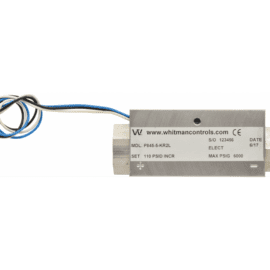

P805 Pressure Transmitter

The P805 Industrial Pressure Transducers are compact, rugged pressure transmitters with silicon piezoresistive sensors packaged in stainless steel housing. These precision engineered devices provide absolute, gauge, and sealed gauge pressure measurement up to 8700 psig with a variety of output signals available. These devices are suitable for applications across process control, including hydraulic systems and valves, refrigeration and HVAC controls, level measurement, and test equipment. In addition to pressure ranges and output signals, a wide range of process and electrical connection options are available to meet any end user demands.

T3 Capillary Thermostat

The T3 Economical Stainless Steel Thermostat has grown in popularity given its versatility, with use across any number of applications. It is a capillary bulb thermostat, with 39” capillary tubes, and stainless steel wetted material. These are SPDT devices rated to 10 Amps. These switches are frequently used in the medical field and food processing, specifically to control the temperature of foods and various enclosures such as chicken coops. They can be panel mounted and used in O.E.M and other various one-off applications.

P845 Differential Pressure Switches

The Whitman Controls P845 Differential Pressure Switches are rugged and versatile, with excellent by-pass characteristics and the ability to handle a wide variety of media to 6,000 PSIG and set point ranges to 250 PSID. These switches are NEMA 4 rated and can tolerate submersion. They are commonly used across oil and water filter heads to detect when a filter element needs changing. It may be mounted in any orientation and is capable of carrying light to moderate mechanical shock and vibratory loads.

KEY APPLICATIONS