Chemical

As far back as the so-called primordial soup, the history of the world is that of chemical reactions and all the interesting things they’ve led to. The Industrial Chemical manufacturing sector has picked up where mother nature left off, affording us the wonders of modern materials found in virtually every aspect of our lives, largely thanks to advanced, safe chemical process controls.

CHALLENGES

Industrial Chemical manufacturing sits at an interesting crossroads today – the next generations of electronic, food, life science, and material science discoveries are soon to emerge from bleeding edge chemistry-based technologies, while at the same time public sensibilities increasingly push for more naturalistic processes in the name of sustainability.

HIGHLY HAZARDOUS, AGGRESSIVE ENVIRONMENTS

➤ Industrial chemicals are inherently hazardous in one way or another, be it risk of explosion, fire, corrosion, suffocation, inhalation, contact burn, exothermic heat, or any number of dangerous reactions. Even in a normal, idle state, most chemicals are aggressive towards materials they contact, risking potential failure. As such, Industrial Chemical processes require the absolute highest levels of safety, reliability, and accuracy of their control system

INTENSE REGULATORY, PUBLIC, AND SOCIAL SCRUTINY

➤ Manufacturers of chemical products are the recipients of increasingly pungent public criticism over environmental and sustainability concerns, reinforced by persistent social scrutiny pushing such concerns into actual law. While difficult to navigate such quickly changing external pressures and requirements, this is a positive opportunity for Industrial Chemical producers to evolve their process control platforms in responsible, conservation-minded ways.

LOCAL PERFORMANCE ON A GLOBAL STAGE

➤ The global Chemical industry is currently experiencing its largest growth overseas, in regions where safety, environmental, pollution, and quality protection provisions are nowhere near western standards. Domestic manufacturers are forced to compete on this uneven playing field, making the game one of maximizing compliance at the absolute minimum economic cost in order to stay competitive.

SOLUTIONS

Whether we’re dealing with lab-scale pilot reactors or full-site chemical process plants, Whitman Controls’ application engineers are right at home discussing process control instrumentation in the Industrial Chemical sector. Our solutions are especially well tailored for ultra-pure, agriculture, life science, polymer, and specialty chemicals, as well as central chemical plant utilities.

Ultra-Pure, Ultra-Reliable Sensor Technology

Ultra-pure, fully traceable applications demand instrumentation that is not just a match in specifications, but is completely manufactured and delivered under high-purity procedures. Whitman produces Ultra-Pure sensors featuring austenitic stainless-steel materials, electron beam welds, helium leak-checking, NEMA 4X housings, documented pre-ship cleaning and sealed packaging. Further, our Ultra-Pure sensors have industry-leading cycle, temperature, pressure, and set-point ranges that assure high reliability in the most sensitive applications

ISO Quality Control

Our product quality may speak for itself, but how can we assure this before you put our instruments into use? Whitman Controls is an ISO 9001 Certified business, providing you with the assurance that our products are entirely designed, manufactured, tested, and delivered using third-party verified practices, complete with total process documentation, material traceability, and chain of custody control.

Conventional Solutions to Emergent Applications

While an application may be novel in its field, diligent engineering review often finds that a standard or semi-standard solution can be made up by piecing together conventional components – the magic being in the way these components are applied and configured. Our experienced engineers can help break down complex, emergent projects to help you navigate options between standard and custom instruments.

Full Product Customization and Value-Add

Our predefined product catalog of hundreds of instruments is only the tip of the iceberg here at Whitman Controls. We can fully customize virtually any of our product models to your exact needs. We're especially excited about emergent applications and highly technical challenges, and can help you with one-off R&D samples as well as high volume production runs of your World's First instrument design, plus custom wiring harnesses, adaptors, and kits.

CHEMICAL APPLICATION

PRODUCTS

Whitman Controls offers multiple instrument, switch, and transmitter models that are engineered to match the demands of the Chemical Industry, such as these below related products.

P802 Series Industrial Pressure Transducer

The P802 Series Pressure Transducers are all-welded stainless steel sensors with pressure ranges up to 20,000psig. These devices are highly configurable with numerous fitting and electrical connection options, allowing use across a range of media and applications. The composition of these units make them ideal in more rugged environments where accuracy of measurement is critical.

ToughSonic CHEM 10 Level Sensor

The Toughsonic Chem Ultrasonic Sensors are the more rugged version of the Toughsonic General purpose line, suitable for use in diesel fuels and chemical level applications in closed or open tanks. These durable, compact ultrasonic level sensors measure a wide variety of liquids from diesel fuel in rail locomotives to chemcial tanks in the paper and food processing industries.

The Toughsonic Chem 10 sensor provides non-contact measurements at distances up to 10 feet (3m), with an optimum range of 4 to 80 inches (100mm to 2m). Heavy duty electronics are epoxy potted into a polyvinylidene fluroride (PVDF) housing that physically isolates the transducer and electronics from chemicals and can withstand exposure to both acids and bases.

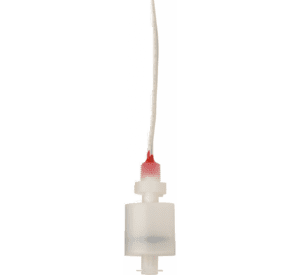

L40 Kynar Plastic Liquid Level Switch, Vertical Mount

Typically used in solvents and certain bases. Durable to 100 PSIG. Submersible to a NEMA 6 rating.

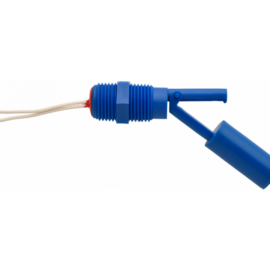

L20 Polypropylene Plastic Liquid Level Switch, Side Mount

The L20 Series Side Mounted Polypropylene Liquid Level Switches are among the most versatile and durable of the side-mounted liquid level switch line. The polypropylene wetted material makes the switch highly compatible with numerous liquids from acids, to water, to bases. The side mount provides added versatility, allowing the switch to be used as a high or low level indicator, and plastic body provides use up to 100 PSI.

P605 SS High Pressure, Fine Adjustment Pressure Switch

The P605 Pressure Switches are a line of severe application controls that can withstand massive pressure spikes from hydraulic systems. These switches can see pressure spikes to 9,000 psig without comprising switch integrity or functionality. They also afford the end user higher set points to complement more severe environments and low set point repeatability.

W117LV Ultra Pure Long Body Vacuum Switch

The W117LG NEMA 4 Ultra Pure Stainless Steel Pressure Switches have all welded stainless steel interiors which are Helium leak checked to pass 4 x 10-9 Std cc/sec. These are the NEMA 4 rated weather-proof, liquid-resistant version of the W117G, suitable for out¬side applications or in areas of condensing humidity.