There are many different ways to monitor liquid levels in industrial processes, each generally designed to serve a certain band of applications within specific industries. Only a few technologies might be considered to apply universally across most types of projects, with the best example of this being hydrostatic level measurement. In practically all process, manufacturing, agricultural, and utility facilities we’ve visited, there’s always at least one hydrostatic level sensor found somewhere on the property. In our opinion, hydrostatic level sensors are so popular due to their very attractive combination of high accuracy, simple sensing technology, competitive costs, and long-term stability. If you haven’t met hydrostatic level sensors before, let’s introduce you!

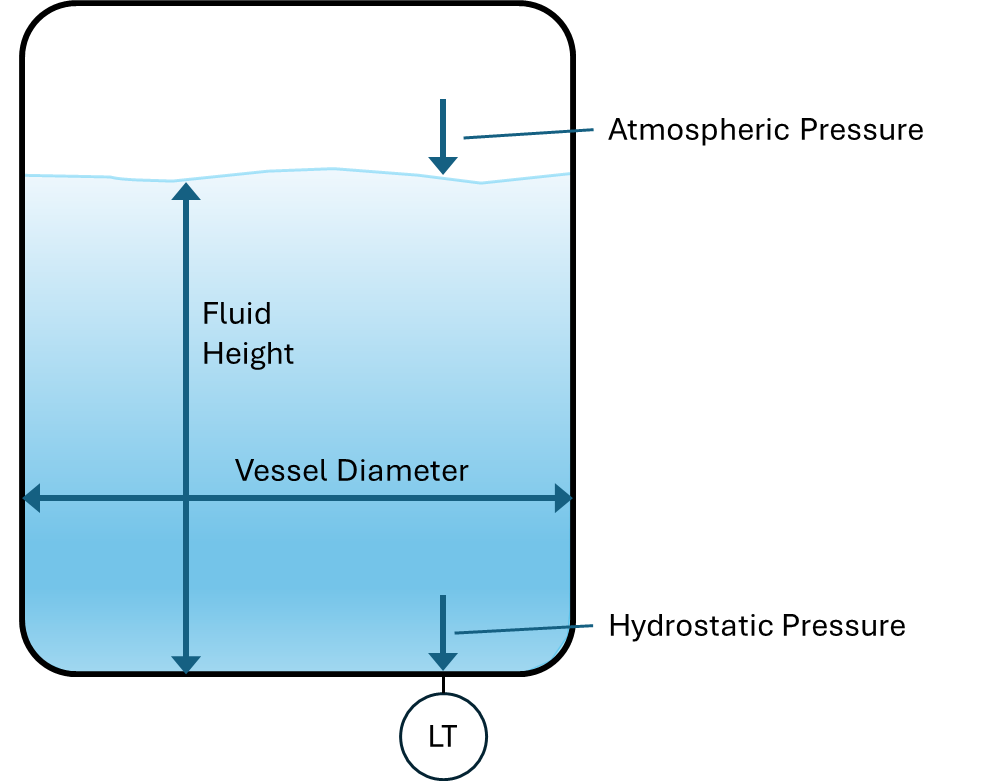

Fig. 1 – Hydrostatic Pressure Principles

In the illustration above, we can see a process tank full of water and an “LT” level transmitter mounted to the bottom of the tank. Let’s say that this tank is open to atmosphere and is cylindrical in shape with a flat bottom. Since water takes on the shape of the vessel it’s held within, the water volume itself is a cylinder too, forming what we refer to as the “water column”. Thanks to physics, we can derrive several neat things about this water column:

- The water column’s weight exerts a force evenly distributed over the surface of the tank bottom.

- This force is caused by gravity pulling “down” evenly on all molecules of water in the water column.

- The height of the water column directly changes this force. That is, as the height rises, the force increases, and as height drops, the force decreases.

- We call this force “hydrostatic pressure”, and measure it in pressure (force) units such as pounds per square inch (PSI) or bar.

- By measuring hydrostatic pressure and then deducting the influence of atmospheric pressure, we can calculate an extremely accurate water column height, also known as tank level.

- In industrial process controls, sensors known as hydrostatic level transmitters perform the above analysis automatically. Further, if you know the vessel’s true diameter (or length and width if not cylindrical), you can program level controllers to directly convert the sensor’s level reading into engineering units such as gallons or pounds of water.

Now that you have a good understanding of hydrostatic level measurement operating principles, let’s dig into the instrumentation side of things next.

A Quick Overview of Hydrostatic Level Transmitter Styles

To measure hydrostatic level, two things are needed: one, a sensor element that makes direct contact with the liquid being measured, and two, an electronic transmitter that translates the sensor element’s excitation into an analog current output. Collectively, these two pieces are known as a hydrostatic level transmitter. Transmitters provide continuous analog electrical outputs (typically 4-20mA or 0-10V) that connect to downstream level displays, level controllers, PLCs, and more advanced control systems. This allows operators and process automation systems to have real-time insight into a vessel’s level without having to physically see or gauge the tank itself.

Fig. 2 – Whitman L95 Hydrostatic Level Transmitter

There are two main styles of hydrostatic level transmitters available on the market for process control applications:

- Submersible Style – with a submersible hydrostatic level transmitter, the sensor element and transmitter housing are separated by a long cordset. The sensor element and cordset are lowered directly (or submersed) into the liquid volume being monitored, and the transmitter housing is mounted above the liquid body. Submersible style transmitters are ideal for large, outdoor, below-ground vessels due to their simple installation method of just dropping the cordset in from above.

- Compact Style – with a compact style transmitter, the sensor element and transmitter are assembled into a singular shared housing. This style transmitter is installed on the exterior bottom sidewall of a vessel, with only the tip of the sensor element touching the liquid being monitored. Compact style units are preferred for above-ground process tanks whose interiors must be kept free of fixed objects, and where high accuracy, easy maintenance, and sanitary requirements are present.

Beyond housing styles, there’s another important detail to know about available hydrostatic level sensors: reference pressure differences. We said earlier that hydrostatic level works by referencing atmospheric pressure for atmospheric tanks, referred to as “atmospheric pressure reference”. In addition, there are “absolute pressure reference” models that do not deduct the atmosphere’s influence, and “differential pressure reference” models that are used for pressurized tanks (measuring the separate airspace and liquid spaces directly to derrive level).

Ideal Applications and Selection Tips for Hydrostatic Level Control

To put the above concepts into practice, next we’ll share a handful of hydrostatic level transmitter application examples, along with a few selection tips to ensure great results:

- Well Water Level Monitoring – submersible hydrostatic level transmitters are routinely used in water wells to monitor groundwater levels and alert property owners of declining water levels that can lead to pump damage. In these applications, NEMA 3 or 4 rated enclosures are preferred for outdoor exposure, up to NEMA 6 where flooding can occur that would submerge the transmitter completely.

- Chemical Storage Tanks – in chemical processing, many volatile chemicals are stored in above-ground tanks that require remote level monitoring and safety management. For these applications, compact hydrostatic instruments are installed on the outside of the tanks, and should be specified with advanced sensing diaphragm materials (such as ceramics) compatible with the chemicals’ aggressive properties.

- Potable Water / Fire Water Tanks – large potable and utility water tanks (such as those storing fire protection water) need online “set and forget” type level monitoring to ensure that volume is always available, which submersible hydrostatic sensors are great for. In potable water systems, stainless steel sensor elements and NSF-rated cord materials are preferred so as not to contaminate the water.

- Captive Ponds & Reservoirs – agricultural, municipal, institutional, and many other large developed sites use stormwater, leech water, and irrigation ponds to manage surface water volumes. Submersible hydrostatic level transmitters are frequently used for logging pond levels over time, helping facility personnel fill and drain ponds proactively. Sensors here can often be selected for lower accuracies to save a few dollars.

- Thermal Liquid Processing – many thermal processes such as dairy evaporators and cooling water condensers share the attributes of being sealed from outside atmosphere and having wide temperature swings. Absolute pressure reference, compact style hydrostatic level transmitters work great for these applications, especially when selected with industry-specific ratings (EG, hygienic food-grade construction).

- Central Plant Utilities – industrial manufacturing and process facilities utilize all types of central plant utilities that compact hydrostatic level transmitters are ideal for, ranging from chilled water recirculation tanks, hot water expansion tanks, and bulk chemical distribution tanks. So long as liquids are relatively clean, free of heavy particulates, moderate density, non-stratefying, and consistent in temperature, hydrostatic level is the way to go.

—

As a veteran-owned small business, Whitman Controls is dedicated to supplying premium quality, reliable, technologically advanced instrumentation for use in nearly any application. Our Bristol, CT manufacturing facility embodies over 40 years of engineering, fabrication, and customer service expertise, serving both end-user and manufacturing customers nationwide through direct and distribution channels. Our values drive us to provide the highest level of servant partnership that you can find. To discuss your applications or to learn more about our capabilities, please contact us at (800) 233-4401, via email at info@whitmancontrols.com, or online at www.whitmancontrols.com.